- mail@sambeetequipments.com

Menu

The rotary screw air compressors from ELGi are the backbone of varied industrial applications.

ELGi’s range of rotary screw air compressors comes with high-end designs, advanced features, and technologies that offer cost-effective, long-lasting, reliable & premium compressed air solutions suitable for light to heavy-duty industrial applications.

ELGi’s EG series rotary screw air compressors represent a giant leap in design and performance, with every single component designed for reliability and ease of maintenance. In addition, each rotary screw air compressor is designed and manufactured in compliance with applicable international standards (CE, ASME, UL, and others). The EG series rotary screw air compressors offer the lowest oil carryover in the industry. Their ability to perform at extreme temperatures makes them suitable for various industries.

WHAT IS THE WORKING PRINCIPLE OF THE ROTARY SCREW AIR COMPRESSOR?

Here we will go through the basic principle of Rotary screw air compressors.

The Screw air compressor uses a rotary-type positive-displacement mechanism. The screw element consists of two rotors similar to a helix, each with a different shape and number of grooves/ teeth. Atmospheric air is sucked into this screw element, and as the air progresses along with the rotors, it gets compressed. The main characteristic is a male and a female rotor element that brings the air to trap and release when required.

In an oil-lubricated rotary screw type air compressor, the male rotor is driven by the motor or engine, and the female rotor is driven by the male rotor, or actually by the thin film of oil that’s between them.In an oil-free rotary screw type air compressor a set of gears control the timing between the male and female rotor. There is no oil to seal the chamber.

The basic principle of a rotary-type screw air compressor is that the male and female rotors spin in opposite directions. The prime mover turns the rotor of the airend in a rotary screw air compressor. This develops a vacuum which results in surrounding air being driven into the airends through the air filter. As the rotors turn progressively, the air gets trapped in the spaces between the two screws (rotors).

Air is taken from the atmosphere into the rotary screw compressor through the air intake system. First, it passes through a filter that helps in removing suspended particles from it. Next, the filtered air goes in the airend, which is the heart of the rotary screw air compressor. Here the air is trapped within the spaces between the two rotors with lobes that mesh with each other. As the rotors turn, they progressively compress the trapped pockets of the air, discharging the compressed air at the outlet of the airend.

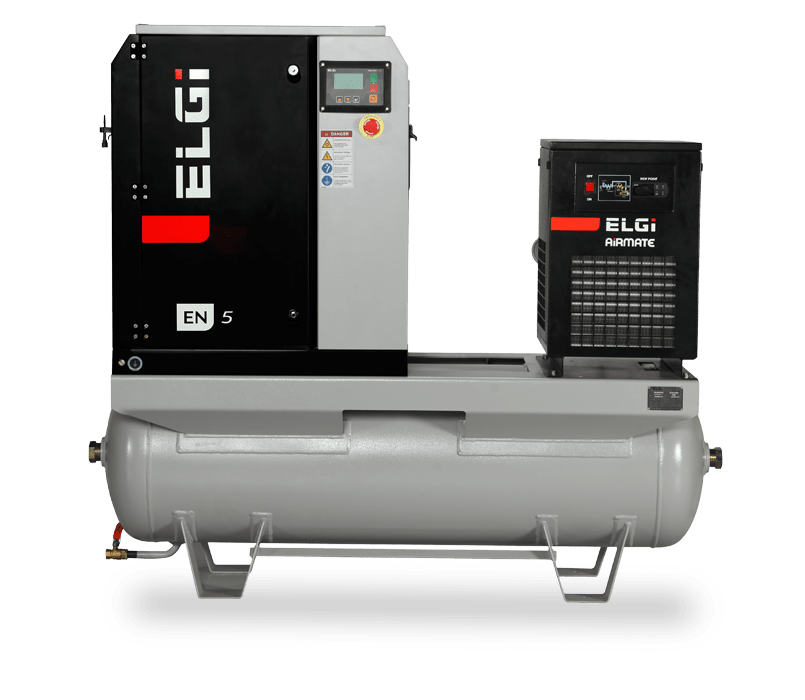

ELGi’s EN & EG series are good examples of best-in-class rotary screw electric air compressor technology, an ideal footprint for industrial applications.

Industries like food, beverage, and textile use rotary screw air compressors for their operations. The rotary screw air compressors are used in various applications like food processing plants, breweries, etc. Food and beverage companies rely on rotary screw air compressors to keep their finished products fresh. Textile companies make use of these compressors for drying purposes. In addition, farms commonly use them to run sprayers that work on liquids like insecticides, liquid fertilizers, etc., easily carried by compressed air.

Sambeet Equipments Pvt. Ltd. Product Display Center is situated in the Hub of Cuttack’s Commercial Belt at Link road.

Copyright © Sambeet 2023. All rights reserved Designed by grainemedia