- mail@sambeetequipments.com

Menu

ELGi Reciprocating air compressors are designed to work efficiently in various industrial applications. The wide range of ELGi reciprocating piston compressors offers reliable, quick & easily maintainable compressed air solutions. ELGi reciprocating compressors come with a portfolio of oil-lubricated pistons ranging from 1-2 HP single drive, 1-3 HP belt drive, and high pressures to 3-40 single & two stages industrial air compressors. ELGi also has an extensive range of oil-free piston air compressors ranging from single & two stages.

ELGi’s single-stage belt-drive reciprocating piston air compressors are designed for continuous duty applications. Our reciprocating air compressors are reliable workhorses that can generate up to 10 bar (g) pressure, suitable for most general engineering and automotive industrial applications. These reciprocating air compressors are designed for continuous duty with automatic start and stop loop control. The ELGi 1-3 HP single-stage reciprocating air compressors come with aluminum cooler tubes, an aerodynamically designed fan for efficient cooling, and a pressure relief valve for extra safety. These reciprocating piston aur compressors are applicable in garages, LPG dispensing units, small manufacturing workshops, etc.

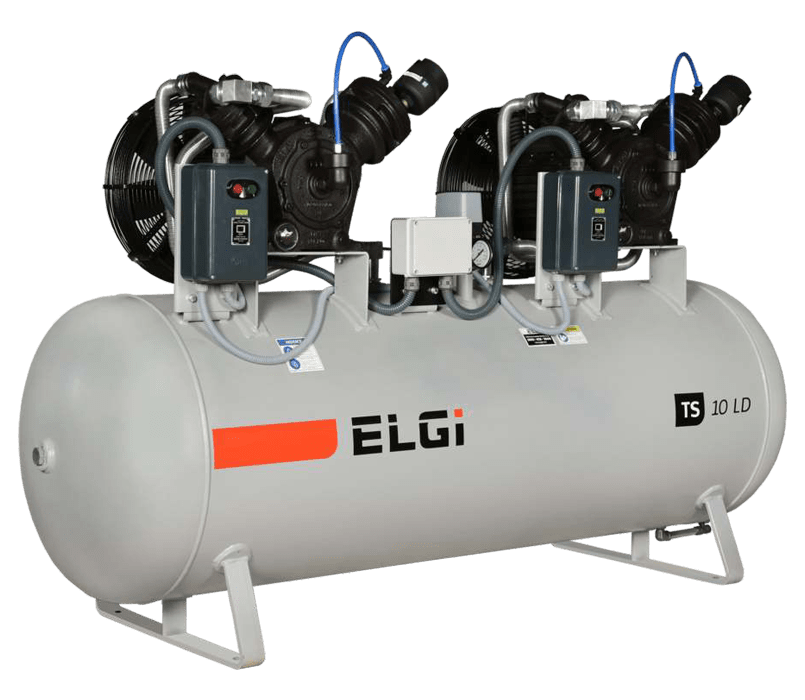

3-10 HP TWO – STAGE DIRECT DRIVE RECIPROCATING AIR COMPRESSOR

ELGi’s LD series reciprocating air compressors are designed to offer time-proven reliability at low operational speed and assure minimum direct cost with high energy savings. The reciprocating air compressors are ideal for customers looking for a significant impact on power, cost, low noise capacity, small air demands, and long-running capacity of more than 8 hours a day. The ELGi reciprocating air compressors are reliable and come with a unique integrated drive and a highly efficient IE2 6 pole motor. They are suitable for automobile, textile, food & beverages, paint shot, plastic manufacturing, CNC operation, and metal fabrication sectors.

3-40 HP SINGLE & TWO STAGE INDUSTRIAL RECIPROCATING AIR COMPRESSOR

ELGi’s industrial single and two-stage reciprocating air compressors are known for their reliability and performance, making them a preferred choice for industrial applications like automotive garages, woodworking, small and medium fabrication units, etc. These reciprocating air compressors are designed for optimum efficiency while requiring minimum maintenance to meet compressed air needs. These piston reciprocating air compressors are robust with internal solid parts. They come with leak-proof fittings and deep-finned cylinders for efficient heat transfer.

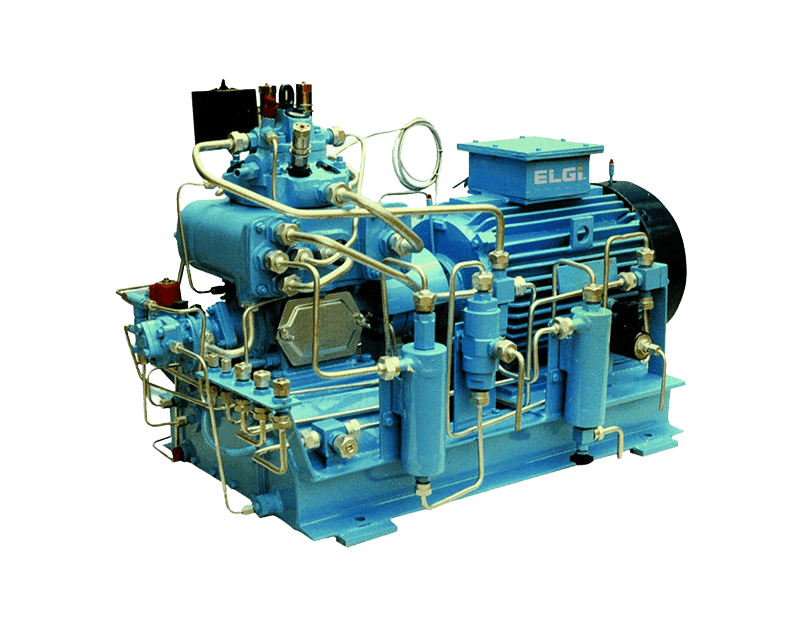

3-20 HP HIGH PRESSURE RECIPROCATING AIR COMPRESSORS

ELGi’s robust three-stage high-pressure reciprocating air compressors come with suction loaders for optimal energy consumption and safety valves for enhanced safety. In addition, these reciprocating piston air compressors are equipped with an efficient cooling system with double Poly-V belts to ensure low transmission loss, making them highly efficient. These reciprocating piston air compressors are ideal for pet blowing, engine starting, circuit breakers, marine applications, plastic industry, packaging industry, etc.

ELGi manufactures custom-built compressors for varied applications, including mining, diesel engine starting, hydel and concrete pumps. ELGi provides custom-built features specific to your requirements.

Reciprocating air compressors are used for a wide range of pressures, from vacuum to 2000 bar g and more for a wide range of industrial applications. The primary use of piston air compressors is generally to move air at increased pressure. Reciprocating air compressors are used in industrials to process and deliver natural gas, plants producing chemicals, oil refining, and refrigerating technology. Other diversified applications of piston compressors are scuba diving, dental surgeries, laboratories, automotive workshops, and agriculture.

WHAT IS THE WORKING PRINCIPLE OF A RECIPROCATING OR PISTON AIR COMPRESSOR?

The reciprocating or piston compressor consists of a piston, inter-outlet valves, and cylinder with an adequate cooling arrangement, connecting rod, and crank. The working is the same as the compression stroke of two-stroke engines. A single-stage reciprocating air compressor is an air compressor that carries out compression in a single stroke & a two-stage reciprocating air compressor is an air compressor that carries out compression in two strokes and consists of two cylinders.

The basic working principle of a reciprocating air compressor or a piston air compressor is to use pistons driven by a crankshaft to move air at high pressure. The first step in this process is that the piston in the reciprocating compressor moves back and forth in the cylinder by a rotating shaft, known as a crankshaft, using a connecting rod that converts rotary motion to reciprocating action. Either engine or an electrical motor provides the power to rotate the crankshaft. The cylinder is supplied with suction and discharge valves. A suction valve is the one that admits air into the cylinder, and delivery lets out the air once it is compressed. The valves must open and close in a coordinated manner to produce compressed air.

Sambeet Equipments Pvt. Ltd. Product Display Center is situated in the Hub of Cuttack’s Commercial Belt at Link road.

Copyright © Sambeet 2023. All rights reserved Designed by grainemedia