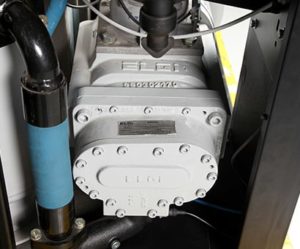

PRODUCT IMAGES

WHY ELGi's EG SERIES SCREW COMPRESSOR?

Best-in-class energy efficiency

Best-in-class energy efficiency

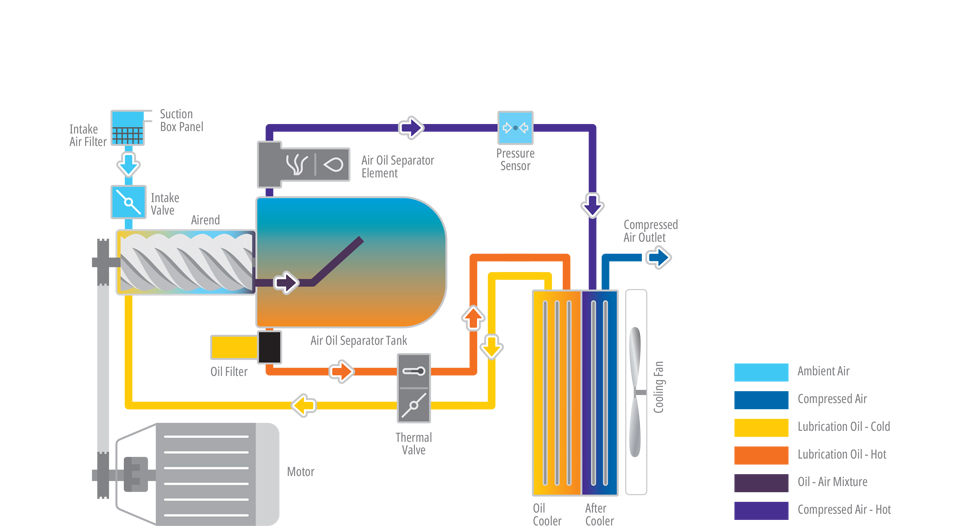

Our EG series has high efficient airends which are equipped with in-house developed eta-V profile rotors, with 4/5 lobe combination, because of the unique design of the rotors it runs at optimum speeds which reduces pressure losses and increases efficiencies and in turn ensure energy-efficient compressed air supply for all demanding applications

Best-in-class maintenance and operating cost

Our EG Series Compressors provide high-quality compressed air in the harshest environmental conditions. Incorporating the next generation technology of ELGi’s oil-injected screw element provides a long and trouble-free life at the lowest possible operating cost

Lowest oil carryover in the industry

Lowest oil carryover in the industry

Because of our unique OSBIC process (Oil Separation by Impact and Centrifugal action) in EG Series Compressor it enables efficient separation of air and oil in 3 stages, delivering consistent oil-free air with minimum pressure drop

Best-in-class warranty program

ELGi comes with Uptime Assurance which is all about giving customers peace of mind by offering industry’s leading warranty which warrants that it’s product and the components for its products will perform the purpose and function for which they are designed and intended for the periods of time indicated when used, serviced and maintained in accordance with ELGi’s instruction and specification

Outstanding reliability stemming from slow operating speeds and low operating temperatures

Our EG series compressors are designed to perform at extreme temperatures – from cold to hot and from dry to extremely humid conditions

Operating data and safety measures

Our EG Series compressors are designed and perfected to ensure highest level of safety for – Pressure regulating valve, High pressure, High temperature, Pressure relief valve, Phase order and single phase

Optional variable speed drives for energy efficiency

Our EG Series compressors have precise rotor clearances for best-in-class energy efficiency resulting in low operating speeds for long life, low maintenance and low sound level. Our in-built Variable Frequency Drives (VFD) matches compressor output with demand by varying motor speed thus the power consumption reduces in line with the reduction in demand which helps in eliminating the frequent load-unload cycle and also the wasted power from the energy bill

SCHEMATIC REPRESENTATION

2.2-45 kW EN Series